MAXLOAD PRO

Take the guess work out of cargo load planning – Know and show before you ship

MaxLoad Pro is a space optimization program for mixed SKU cargo load planning. Accurate container and truck loads are planned with intelligent loading algorithms utilizing extensive stacking rules, vehicle specific characteristics, loading priorities, etc. to optimize the placement of mixed products into containers, vehicles, and pallets.

Some key questions MaxLoad Pro answers…

How does my product fit in my container, truck, ULD, pallet, rail car, etc?

How many pallets, trucks, containers, etc. does it take to fulfill my order?

MaxLoad Pro supplies users with loading diagrams on how to build the pallets and cube out trucks and containers. It increases transport efficiency, ships more products, lowers freight costs and provides better communications among teams, vendors and customers.

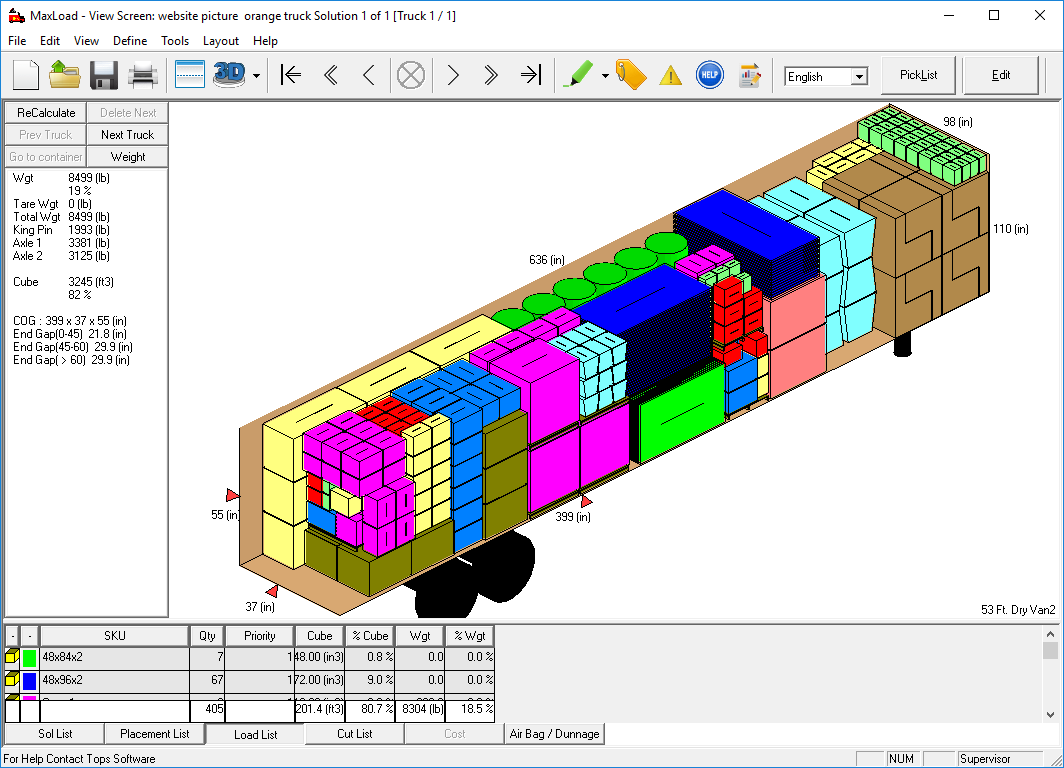

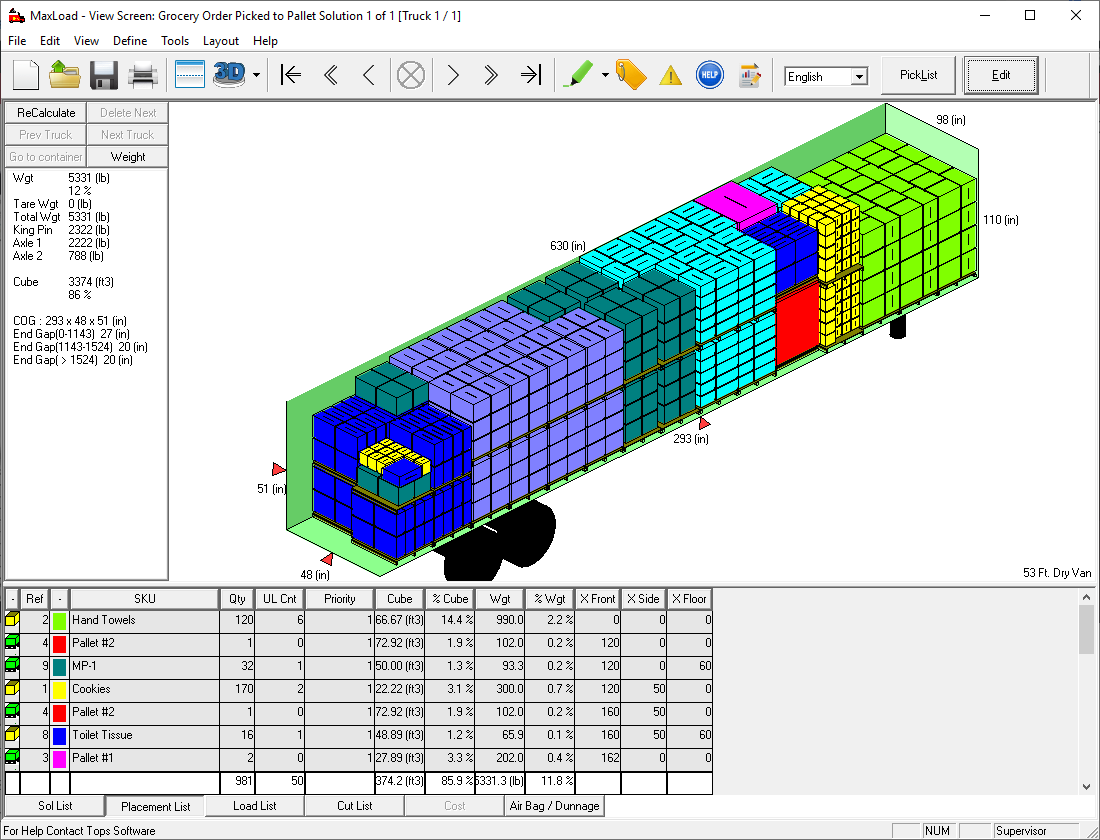

Truck and Container Loading

- Determine the number of trucks or containers needed for the order or shipment.

- 40′ or 40′ HC containers? Compare solutions to find the best mix of vehicles to optimize cube usage and minimize costs.

- Load SKUs as floor loads, uniform pallets or in mixed pallets with other SKUs.

- Load trucks according to stop offs and loading priority of SKUs.

- Enforce load rules and stack codes to minimize product damage.

- Loads cylindrical, L-shaped, trapezoidal and bundled SKUs.

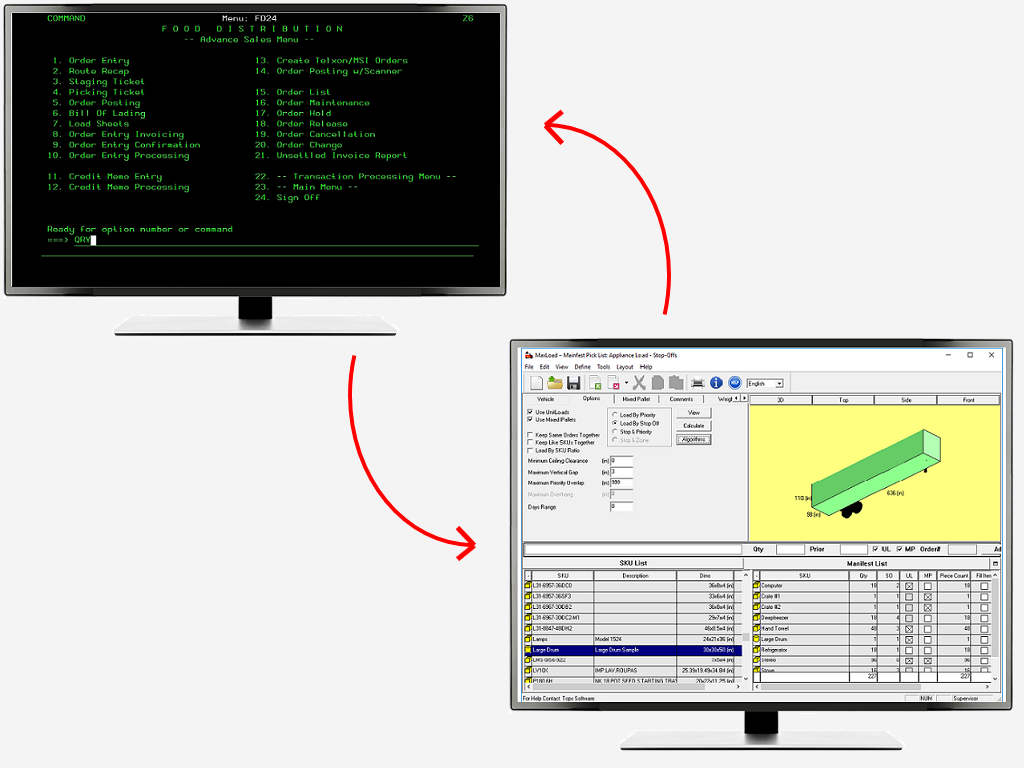

- Import SKUs and order data in from Excel, SAP, ordering or other ERP systems.

- Interface MaxLoad Pro with your TM, WM, or ERP systems to seamlessly transfer SKU and relevant order data.

Loadable SKU Types

- standard regular cartons

- cylindrical SKUs in nested or pyramidal patterns

- single or bundled L-shape SKUs

- trapezoidal SKUs

- SKUs all mixed in the same vehicle, as floor loads, uniform or mixed pallets

Supported Vehicle Types

- trucks

- containers

- railcars

- air cargo or ULDs

- flatbeds

- side bay trucks

- trucks with shelves

- define vehicles with drop decks, wheel wells, corner boxes and more

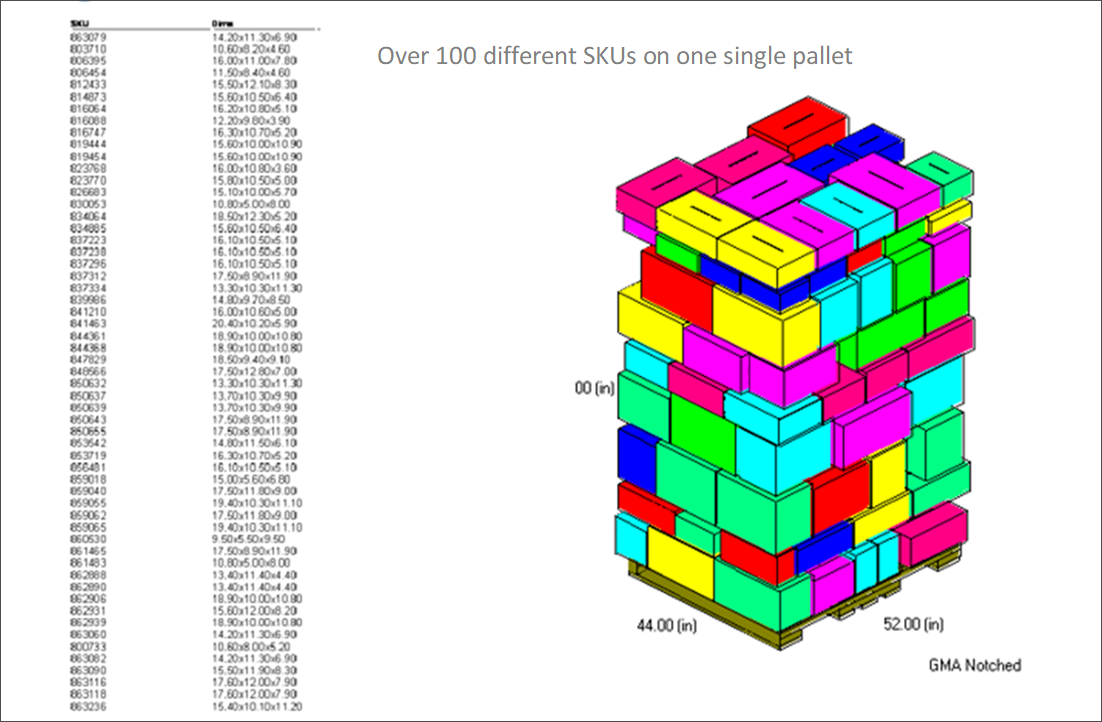

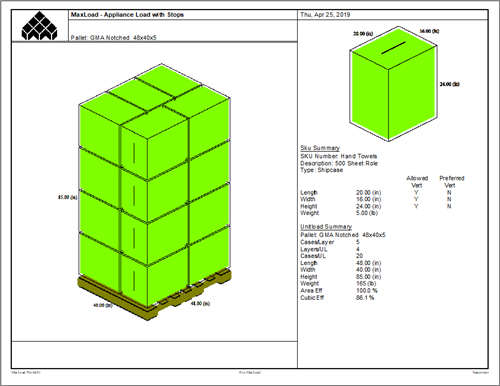

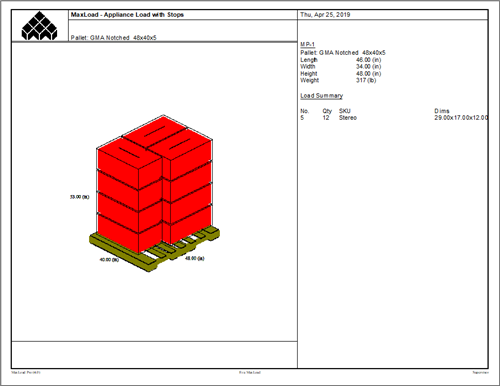

Create Stable Mixed Pallets

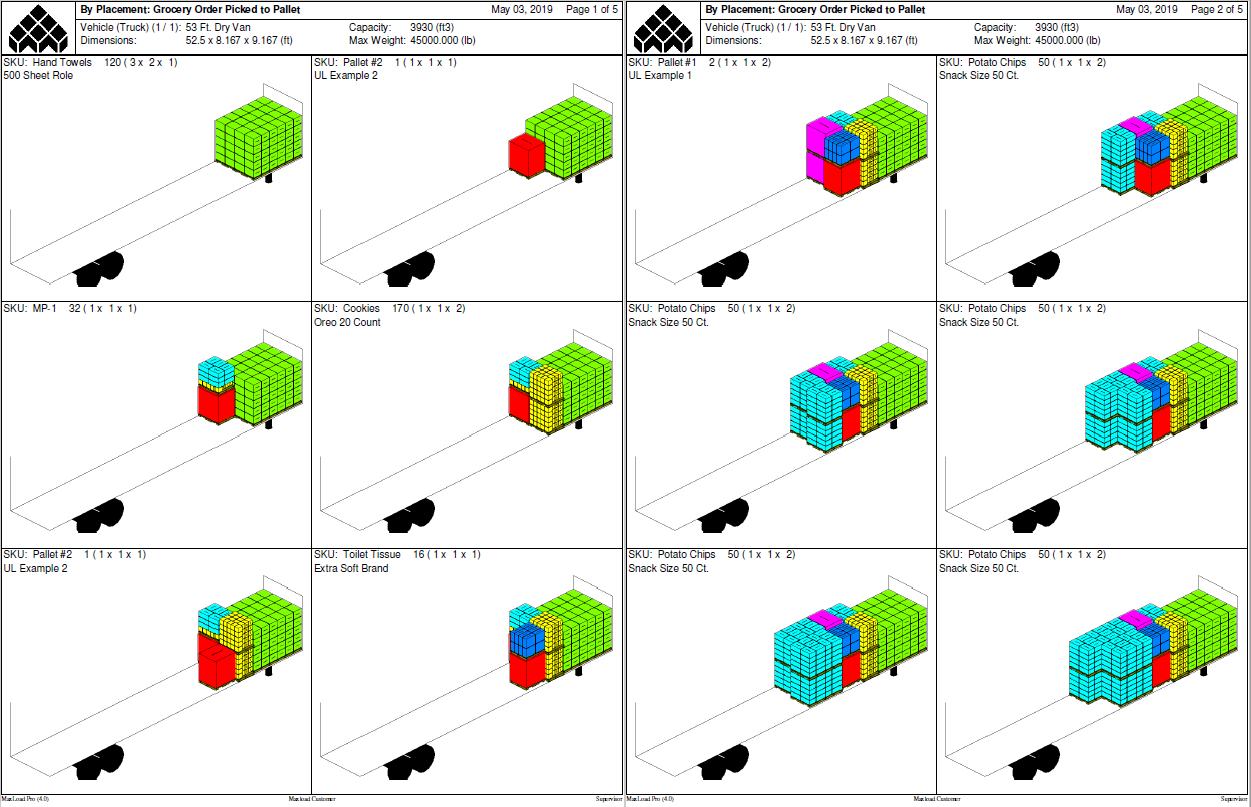

- With 3D load diagrams, get actual calculations, not estimates for stable layer mixed pallets.

- Optimize LTL orders by calculating the number of pallets needed to fulfill an order.

- Know what SKUs are on each pallet and how to build the pallets.

- Improve factory automation through accurate SKU placement data to Robotic Palletizers.

- Provide accurate case sequence data for AS/RS systems.

- Provide picking data to drive voice based and other electronic picking systems.

- Integrate with routing and WMS software.

- Customizable pallet building requirements.

- Ability to run in pure Server Mode “Black Box” and send picking information electronically to build pallets.

Customer Service

- At the time of order entry, calculate freight metrics for planning or consolidation of orders.

- Convert customer orders to pallet or truck/container orders for improved freight quoting.

- Use MaxLoad to calculate the floor space consumed, analyze the remaining linear feet, then accurately increase order quantities to “make the most of every inch.”

- Quickly compare orders as palletized, dead stacked, or mixed loads to fit your business needs.

- At the time of order entry, improve communications with customers by providing a shipment summary, load list and contents of each pallet and truck/container.

- Reduce loading errors and LTL shipments by eliminating the costly “it does not fit” scenario.

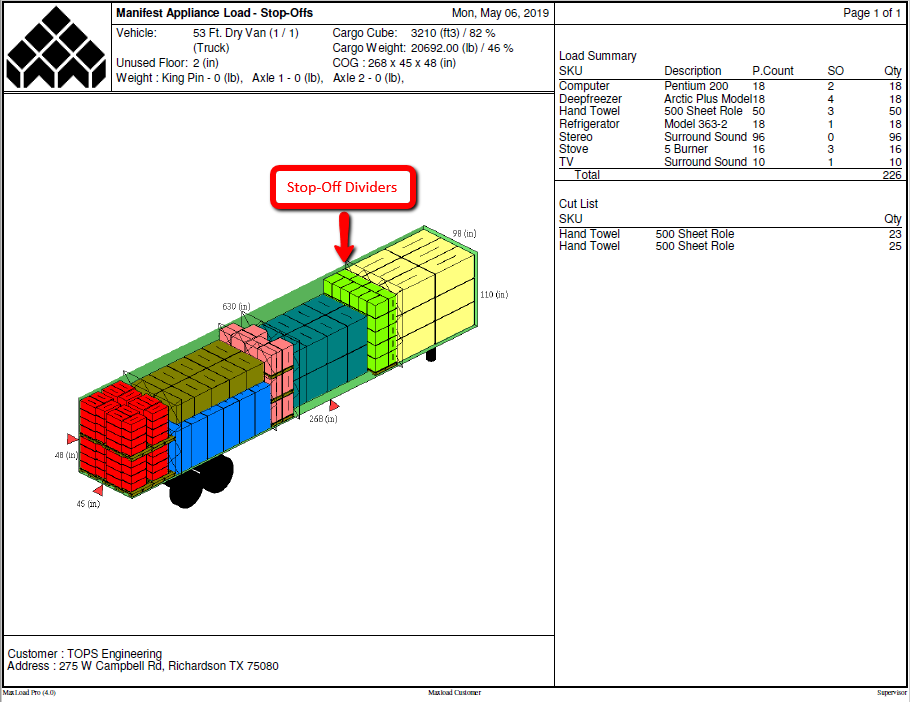

Logistics / 3PL

- Calculate floor space for less than truckload (LTL) and full truckload (FTL) freights.

- Plan LTL freights using priority groups, stops, and orders.

- Allow different loading profiles for different customers.

- Create loading diagrams with step-by-step instructions.

- Placement reports and load summaries provide shipment details.

- Plan drop shipments using load priority or stop offs.

- Multiple options for weight-balancing: segmented loads, axle weights, manual adjustments, etc.

MaxLoad Pro Mixed SKU Truck and Container Cubing Software

New to TOPS Software

Existing Customers

Contact Us

TOPS Software Corporation

1301 Central Expy S, Ste 200

Allen, Texas 75013

972.739-8677

Copyright © 2024 TOPS Software Corporation. All Rights Reserved. TOPS uses copyrighted and patented technology including U.S. Patent No. 5,490,216