MaxLoad Pro Mixed Pallet Loader

Works with palletizer to create mixed pallets for shipment and warehouse storage

MaxLoad Pro’s Optional MPAS (Mixed Pallet Automation Server) offers software solution for generating mixed pallets for warehouse and pallet automation.

Are you Looking for solutions to create stable, mixed pallets to optimize cube and minimize product damage? Searching for a partner to complete your automated palletizing system and drive robots, ASRS, pick to voice, to pick pallet layers and build rainbow loads?

With proven success in delivering mixed pallet solutions to leaders in the food, beverage and retail industries, TOPS has the expertise to devise algorithms and develop the program to create stable mixed pallets for your specific loading requirements. The MPAS will generate pick sequence and placement solutions to integrate with the palletizing systems to meet your business needs.

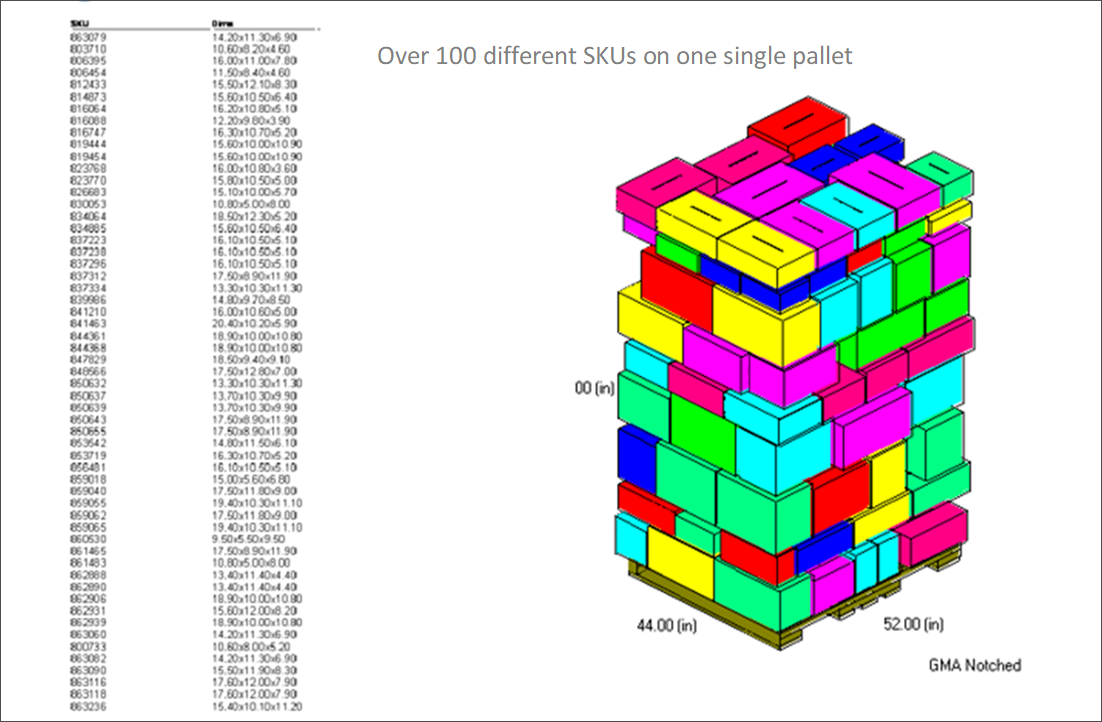

Create Stable Mixed Pallets

- Actual calculations – not estimations

- Create steady and stackable mixed pallets to minimize product damage with use of extensive stacking and loading rules

- Automatically use full pallets

- Use pre-defined Layer configuration

- Ability to create mixed pallet with full Layers and less than full layer quantity

- Balance pallet heights for the same stop to spread “dirty” layers among the pallets and increase stability

- Ability to automatically mix orders if not enough space on truck

- Same SKUs are kept together on each pallet for efficient picking

Integrate Pallet Outout with Existing System for Integration

- Automatically convert customer full orders to pallet orders

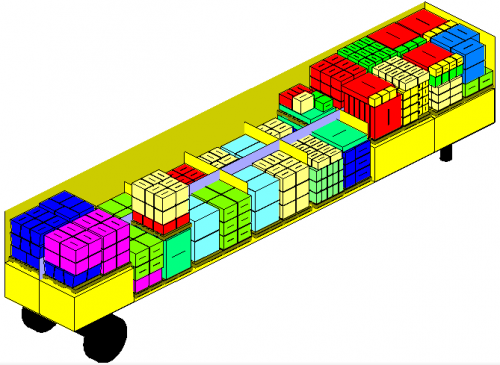

- Build mixed pallets and ability to load bulk trucks by stop or route

- Ability to split bays for side loading trucks and specify which side of the truck to load a pallet

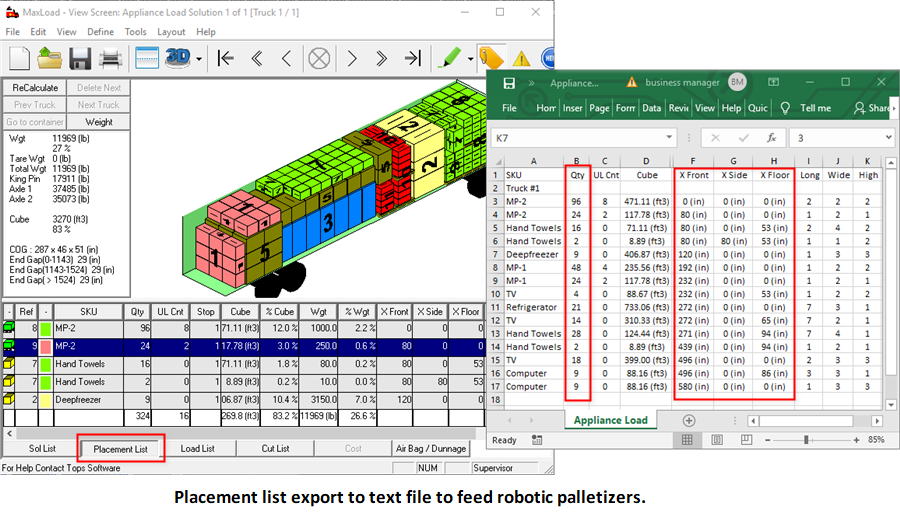

- Provide accurate SKU placement and orientation data to Robotic Palletizers

- Provide accurate case sequence data for AS/RS systems

- Provide picking data to drive voice based and other electronic picking systems

- Integrate with routing and WMS software

- Ability to run in pure Server Mode “Black Box” and send picking information electronically to build pallets

Talk to a Solutions Adviser Today.

New to TOPS Software

Existing Customers

Contact Us

TOPS Software Corporation

1301 Central Expy S, Ste 200

Allen, Texas 75013

972.739-8677

Copyright © 2024 TOPS Software Corporation. All Rights Reserved. TOPS uses copyrighted and patented technology including U.S. Patent No. 5,490,216